Automated warehouse system can complete the automatic access of unit goods under the control of the computer system. Using the collaboration of automated storage devices and computer management systems, it can also realize the rationalization of high-level storeroom placement, thereby reducing errors, accelerating the access rhythm of goods, and improving work efficiency; it improves space utilization, reduces inventory, and saves land investment costs; it reduces labor intensity, improves workers’ working environment, and reduces labor costs; it realizes overall system optimization, and improves enterprise production efficiency and modern management level. At the same time, it improves customer satisfaction and enables fast and reliable traceability of food safety.

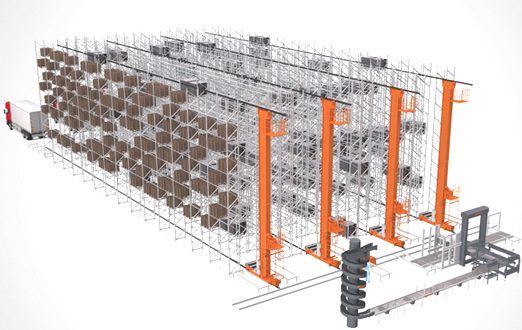

System Components:

Transfer and storage of goods – high shelves and pallets, containers

Inbound and outbound operation equipment – stackers, shuttles, RGVs, AGVs, etc.

Inbound and outbound distribution system – roller, chain conveyor, dispenser, lifter, etc.

WCS control system – including computer-controlled inbound and outbound equipment, distribution systems, and all electronic control devices for various inspection and insurance agencies

WMS warehouse management system – warehouse account management, data analysis, reasonable management of the location, equipment operation and inventory status display, etc.